L&TD

LOGGING & TESTING DIVISION

Mud Logging

1. Introduction

The Mud Logging Team of Logging & Testing Division is an operation unit with function to carry out mud logging services in almost wells of VSP. We have also performed mud logging services for some companies such as PIDC, PVEP, VRJ with many exploitation and exploratory wells. The Mud logging services are performed in either drilling process or workover operations with the possibility to fullfil following functions: to monitor and control drilling operations, to collect geological data, to increase drilling safety.

The Mud Logging Team is a strong team of 35 engineers who have graduated from universities in Vietnam and abroad with profession of Geophysics, Geology and Electronics. Most of them have more than 10 years of experience of Mud logging in oil field. They regularly have various training courses of professional knowledge to enhance the quality and effectiveness of service.

2. Equipments

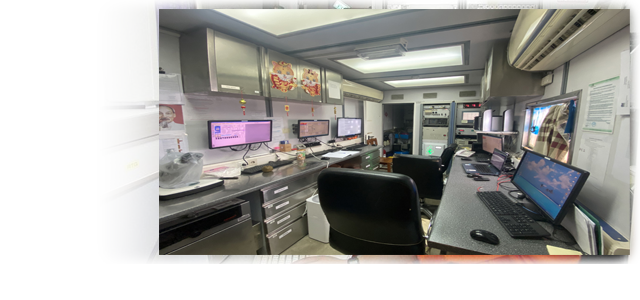

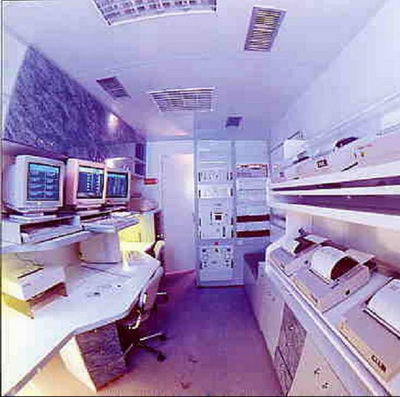

At present, we have 07 logging units. All of them are supplied by Geoservices company: 03 ALS- 3 (Advanced Logging System, third generation) units and 04 ALS-NT unit with modern and reliable gas detection systems - Geo Fast FID.

3 (Advanced Logging System, third generation) units and 04 ALS-NT unit with modern and reliable gas detection systems - Geo Fast FID.

We also co-operate with domestic companies to design, manufacture and activate Advanced Security System, and to upgrade & improve completeness of the equipment. Equipment systems of Mud Logging Units are regularly replaced and upgraded in compliance with modern technology to secure operational correctness and stability.

As other departments of L&TD, we also apply Quality Control System ISO 9001:2008.

Mud logging unit for offshore operation, complete with

- • Air-condition System

- • Explosion Proof Safety Pressurisation System

- • Working area for client

- • UPS System

- • Airlock/Escape Hatch

- • Safety Equipment

- • Intercom System

Formation evaluation equipment

• Microscope

• UV Fluoroscope

• Sample Drying Oven

• Geological Equipment and Chemicals

• Sample Processing Trays

• Shale Density

• Auto Calcimeter

• Geoservices ALS Mud Logging Unit provides highly automated monitoring of the entire drilling operation.

• More than 70 parameters can be measured, processed, displayed, printed and recorded simultaneously.

• The acquisition system also calibrates the received signals and checks the state of the sensors. In the case of malfunction, an alarm is activated immediately alerting the operator

The data processi ng is based entirely on computer technology. The sensor signals are transformed into digital format and then distributed according to requirement. The data is supplied on screen monitors or intelligent interfaces in real-time or play-back mode. Alarms can be placed on each parameter. Computerized print-outs of desired parameters produce graphic charts of the progress of the well being drilled.

ng is based entirely on computer technology. The sensor signals are transformed into digital format and then distributed according to requirement. The data is supplied on screen monitors or intelligent interfaces in real-time or play-back mode. Alarms can be placed on each parameter. Computerized print-outs of desired parameters produce graphic charts of the progress of the well being drilled.

The ALS is a powerful tool which may be placed in the hands of those with responsibility for the drilling rig. Using many forms of data presentation in the logging unit, monitors or intelligent interfaces can be placed anywhere on the rig. These terminals are “operator friendly” and enable anybody who needs information to have it right there in front of him in real-time or replay mode, and to apply analysis programs if necessary.

Gas Detection System – GEO FAST FID

- FID Total Hydrocarbon Detector :

Range: 100 ppm – 100 %

Sensitivity: 20 ppm

Gas measure: Total Hydrocarbon

- FID Gas Chromatograph Detector :

Range: 20 ppm – 100 %

Sensitivity: 5 ppm

Chromatograph cycle: 42s

Gas measure: C1 – nC5

Sensors and Parameters

- Drilling rate, heave, depth, bit depth, TVD depth, kelly height, bit run, bit time o Weight on Bit, Hook Load, Overpull

- Individual Pit Volume and Totaliser (8pits)

- Trip Tank

- Pump Rate, Totaliser & Flow In

- Standpipe and Casing Pressure

- Rotary Speed sensor (RPM)

- Mud Temperature IN/OUT

- Mud Weight IN/OUT

- Rotary Torque

- Mud Flow OUT

3. The Mud Logging Process

Off-line processing

- Calibration of the sensors

- Off-line calculations:

- Overpressure

- Hydraulics (Bingham, Power Law and other model

- Deviation survey analysis

- Surge & Swab

- Drilling bit optimisation

- Bit performance and cost

- Kick control

- Gas ratio analysis + plots

- Data handling (graphic playback, log processing, import/export,...)

- Diagnostic functions and network management.

- Reporting capabilities (word processing, graphic editor,...)

4. Reporting

• Update all logs, prints and plots requested by Client daily and as needed.

• Submit daily reports (Geology, Pressure, Hydraulic, Deviation, Composite logs) to the Client Representatives at the precise time specified by the Client.

• Provide any other reports or documents based on well data as requested by Client.

• Prepare a fully documented, accurate and reliable Final Report as per Client’s specification and formats for submission to Client within 15 days after the completion of drilling.

5. Enhanced Mud Logging Services

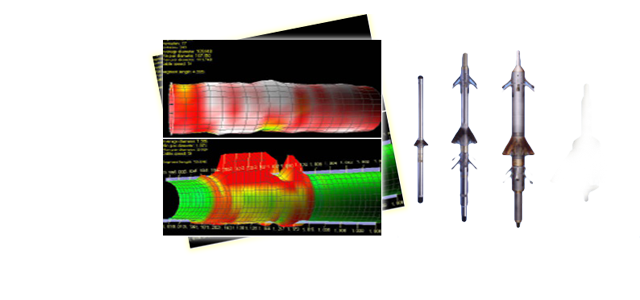

Advanced Securites System (ASS-2010)

Purpose: In practice of drilling on offshore rigs of VSP, there were several cases that drilled well went directly into another neighboring production well and destroyed the casing of this well due to high density of disposition of the wells. So there is a demand to develop Advanced Security System to detect the early stage of the clash (if any)

Functions:

- Automatic detecting of clash between the drill bit and casing of other neighboring production wells.

- Internal Alarm Management.

- Printer management (Print out Real-time and Playback logs).

- Data management: Backup and store of Real-time database.

Principle: The system uses the spectrum analyses of vibration signals by Fast Fourier Transform Algorithm. While drilling, if any clash between the drill bit and casing occurs then the amplitude of vibration signal is increasing and frequency of signal is concentrated in range of 300Hz - 700Hz, and this phenomenon occurs more chronically to go with drilling parameters changes (e.g. increasing of torque and/or decreasing of rate of penetration,..). This is right indication of the clash.

Nhóm Marketing