L&TD

LOGGING & TESTING DIVISION

Sản phẩm dịch vụ

Summomer

1. Introductions

SUMMOMER IS A RELIABLE FRIEND OF THE PETROLEUM WELL-BORING COMPANIES

- Summomer is an outguard equipment which applies in well-boring technology effectively. It aims to alert the impact betweent he drill bit and the neighbor drilled wells or the other wells though more long-distance but canpenetrating risk in the depth of adaptation, especially during drilling diagonally

- When drilling in the insert regime, the distance between the wells will be smaller. If the density of drilling wells under the dense terms, risk of drilling bit impact or puncture nearby wells rise considerably. Or during drilling diagonally the collision can cause problems not foreseen, especially for those wells are exploiting with the huge flow

Tubing Inspection by 24 Fingers MIT

|

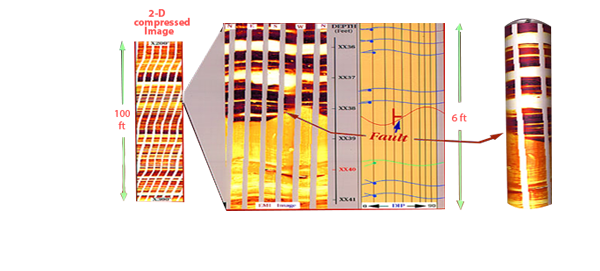

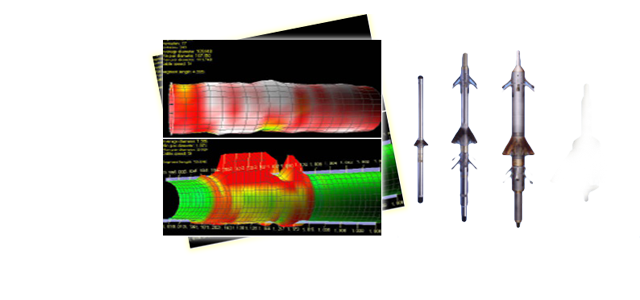

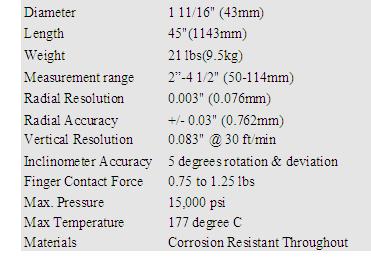

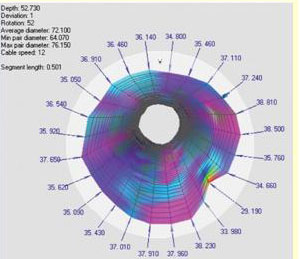

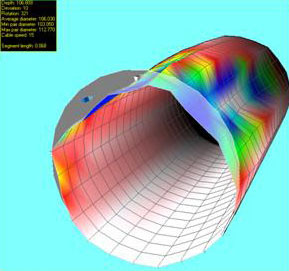

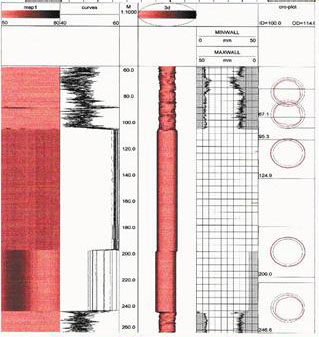

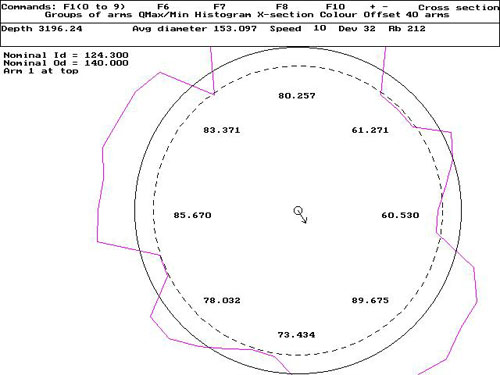

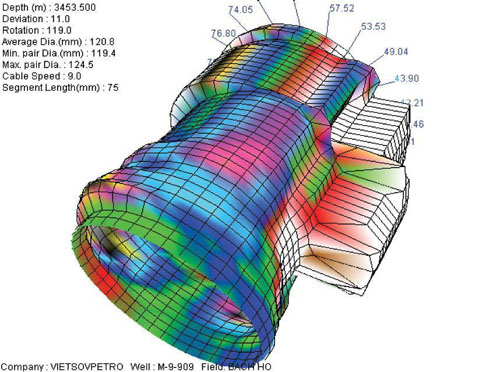

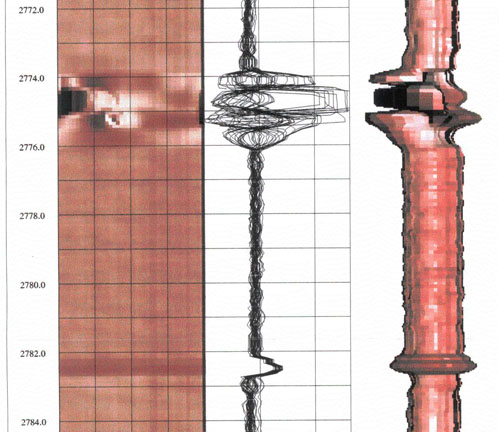

DESCRIPTION The Sondex 24 finger MIT has been designed to provide the most accurate tubing caliper measurements in the industry. The high quality of the data allows for 3 dimensional imaging and the calculation of rates of corrosion or scale deposition. OPERATING PRINCIPLE The tool is run in the hole using mono-conductor cable or Slickline. Once at the bottom the fingers are motored open. The spring loaded, hardened tip fingers push against the ID of the casing or tubing with a low constant force. As the tool is logged up the well, the movement of each finger is transferred to a position sensor. The output of the position sensor is then digitized for recording into memory or transmission up hole. Data from each finger is monitored independently. At the end of the run the fingers are motored closed for pulling out of hole or for repeat logging. The tool contains an inclinometer to denote the high side and well deviation. The temperature of the electronics is monitored for software correction of sensor drift. APPLICATIONS • Quantification of scale build up and corrosion. • Accurate location of holes or anomalies. • Identification of tubing items and damage. INTERFACES & TOOL COMBINATIONS Switch-able for operation with other PLT tools (Ultralink only). OPTIONS Stainless Steel or Beryllium-Copper Fingers. Memory or Surface Readout (Slickline or Mono-conductor cable) MITpro statistical joint analysis software MITview 3D imaging software SPECIFICATIONS (1 11/16" 24 FINGER MIT)

|

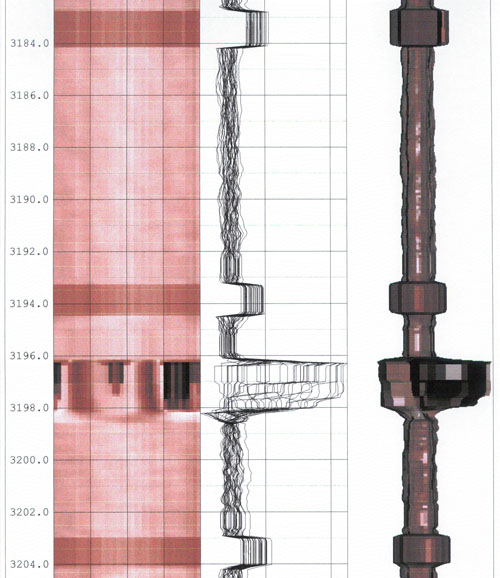

| The MIT-24 is widely used for tubing inspection in Vietsovpetro’s oil fields. Pictures below show some results of 1-11/16“ OD 24 FINGER MIT TOOL. |

|

|

|

|

|

|

Nhóm Marketing

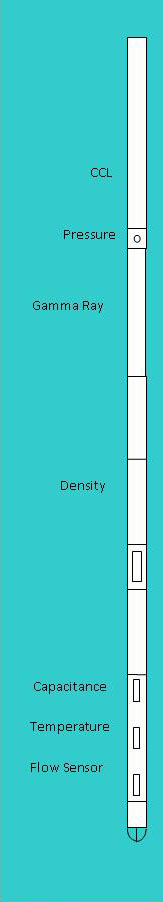

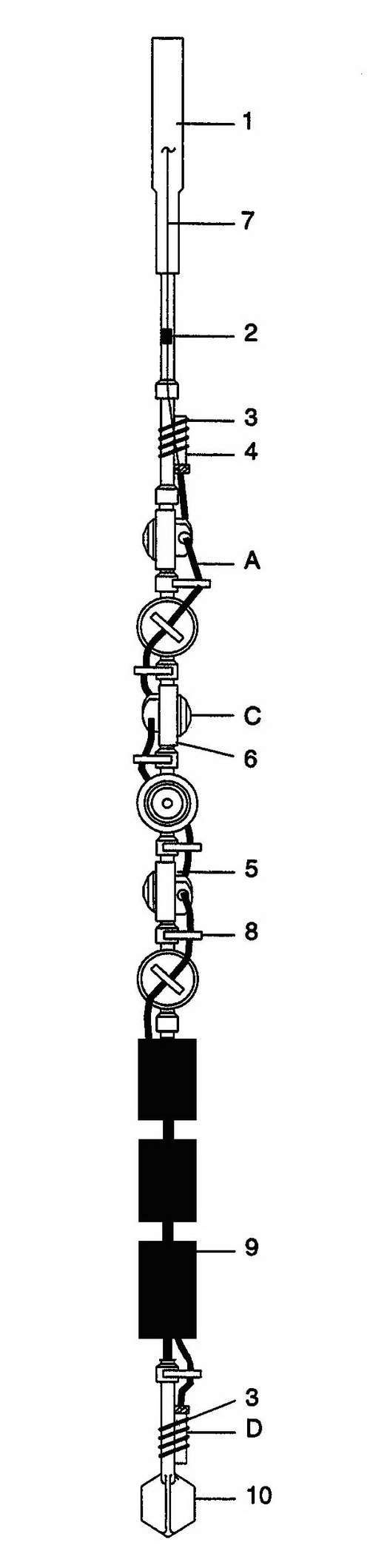

1 3/8” SHORT COMBINATION PL TOOLSTRING

|

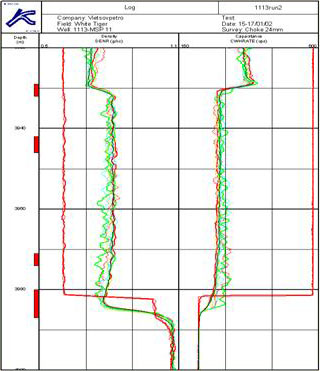

DESCRIPTION This is easily transported toolstring, designed for use where access is restricted. The basic string, with Flowmeter, Temperature, Capacitance, Density, Gamma, Pressure & CCL sensors, can be used for Memory or Surface Readout operations; it can also be extended to include other Sondex tools and will operate a variety of flowmeter mechanical sections. For transportation in a small case, the string breaks down into very short sections. These hae pressure isolation ans can have other tools such as Centralisers, Knuckle Joints ect. Fitted between them. KEY POINTS

SPECIFICATIONS

|

Nhóm Marketing

MWD/LWD

I/ INTRODUCTION

Measuring the properties of geological formations and reservoir fluids has traditionally been performed with logging tools run on an electric wireline, a technique that was developed in the 1920’s.

Advanced Security System (ASS – 2002)

|

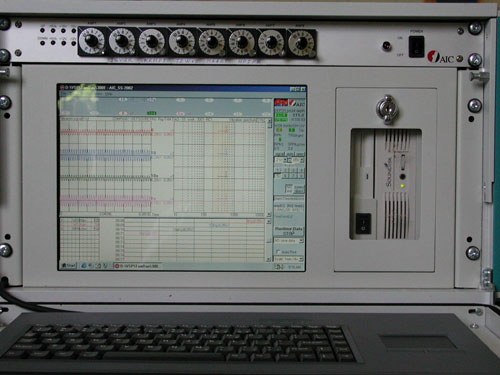

III. ANTI-COLLISION TO PRE-EXISTING WELLBORE WHILE DRILLING - ADVANCED SECURITY SYSTEM (ASS-2002): 1. Introduction: In drilling from offshore platforms there have been several cases where drilling a new well went directly into another neighboring production well and destroyed the casing of that well. This is due to very narrow well-to-well spacing (distance between the wells is 2.5-3.0m). So there is a demand to employ an Advanced Security System to detect this at an early stage before collision. |

| 2. Principle:

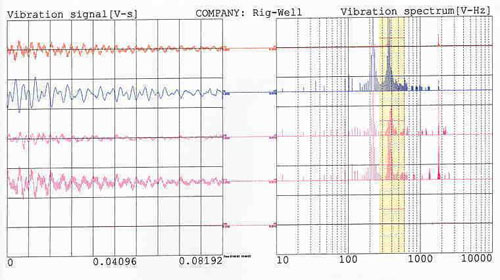

The advanced security system detects the approach of the drill bit to casing of neibouring production wells. Data is sampled at high frequency from vibration sensors (Installed on well heads) and drilling sensors (WOH, RPM, TORQUE, SPP). The system uses the spectrum analyses of vibration signals by Fast Fourier Transform Algorithm. While drilling, if the drill bit approaches a well then the is increasing and frequency of signal is concentrated in range of 300Hz - 700Hz. This phenomenon occurs more serverly with drilling parameter changes (eg: increasing of torque and/or decreasing of rate of penetration,..). |

|

|

3. Functions of the System:

|

|

Nhóm Marketing

MKAB 42-170/100 M

Benefits and Features - MKAB makes high about temperature and pressure for formations.(This is one of advantages when use MKAB). - MKAB always fit up in a lubricator and can use in under balance. -This equipment makes increasing recovery factor and can through christmas tree , tubing and perforate under packer. - During using it, the well may be on situation of exploitation. -The length of the gun may be up to 10 meters. |

|

Nhóm Marketing

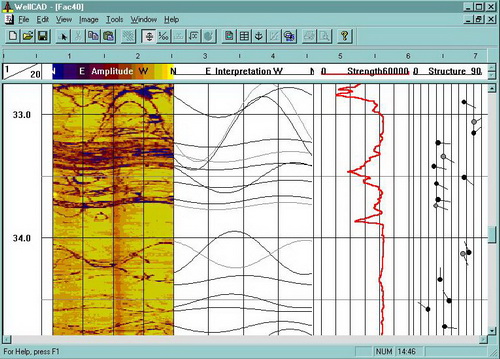

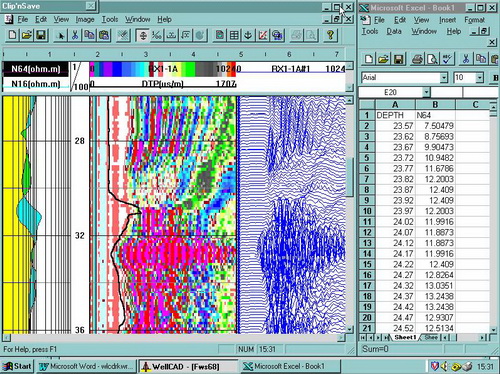

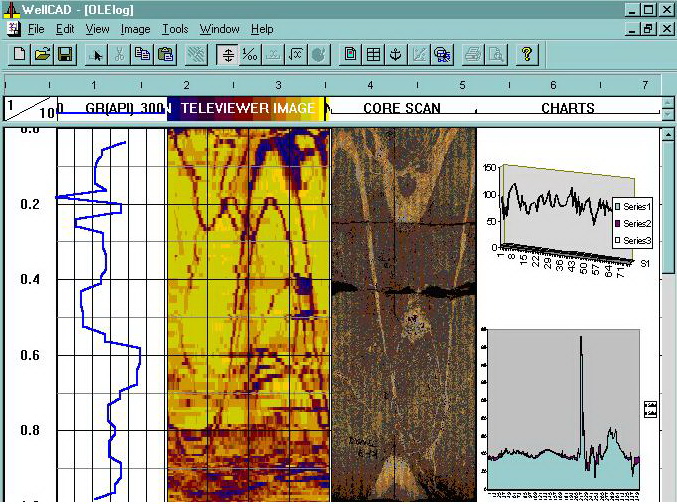

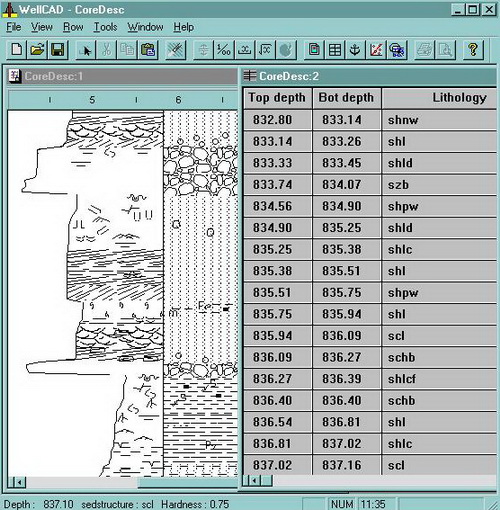

WellCAD SOFTWARE

| WellCAD is one of the most powerful and interactive PC based well data management tools available on the open market.

WellCAD is a single well-oriented system that operates under Win32, the 32 bits application-programming interface (API) from Microsoft.

WellCAD runs on Windows 3.1x, Windows 95, Windows NT and DEC Alpha AXP running Windows NT. WellCAD is OLE2 compliant and supports OLE object linking and embedding, OLE automation and drag and drop between WellCAD documents and other OLE compliant software. |

|

Windows compatibility Compatibility with Windows means that WellCAD printing and plotting is virtually hardware independent. Data exchange between WellCAD and other data sources and repositories is extremely flexible using industry standard file formats and using the Windows clipboard and OLE functionality WellCAD data types WellCAD is capable of handling a diverse range of borehole information all on one document. These data types include:

|

|

|

WellCAD Features

|

|

|

WellCAD tools:

|

|

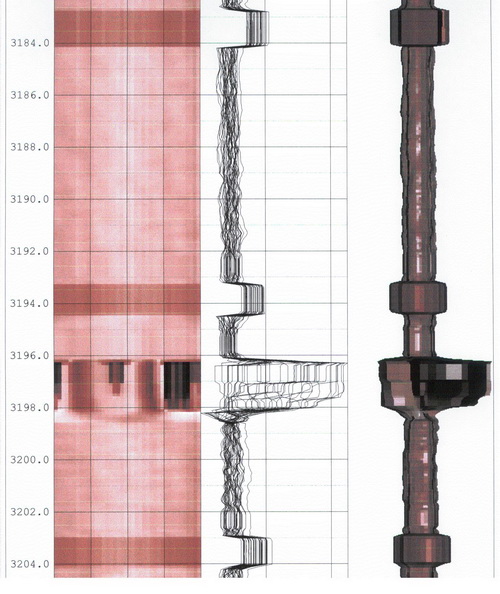

Application in L & TD – VSP.

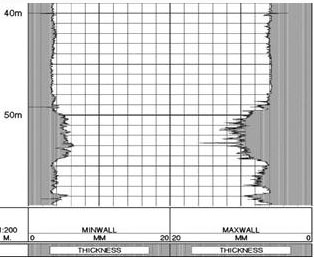

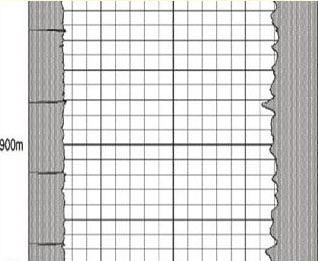

WellCAD is powerful software and has been used for multi-purpose in L & TD. Since 1996 it has often been used for casing inspection quick look analysis plots. This picture presents a casing inspecting result in White Tiger oil field . |

|

Nhóm Marketing

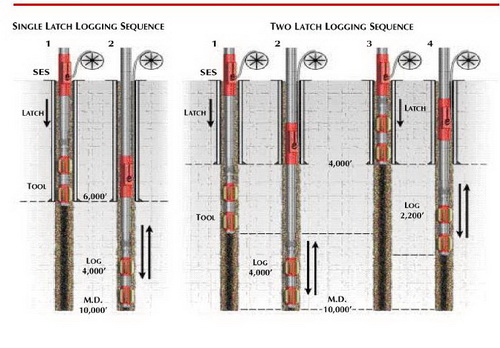

Advantages & Disadvantages

|

ADVANTAGES

DISADVANTAGES

Rig up and logging takes longer than standard logging  Picture of TPL drillpipe conveyed system |

Nhóm Marketing

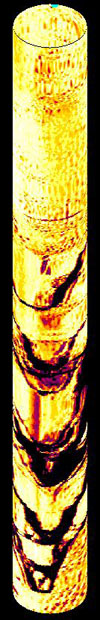

CAST-V Circumferential Acoustic Scanning Tool-Visualable

|

CAST-V – A COST-EFFECTIVE TOOL TO EVALUATE THE POTENTIAL ZONES IN FRACTURED BASEMENT.

The newest generation Circumferential Acoustic Scanning tool, the CAST-V made by Halliburton, provides a wealth of information in both open and cased holes. In open holes, the CAST-V provides complete borehole imaging for accurate formation evaluation. In cased holes, ultrasonic pipe inspection and cement evaluation can now be obtained simultaneously. Operating over a wide range of downhole environments, the CAST-V data can be presented in a variety of two- and three- dimension formats. Powerful, yet user-friendly imaging analysis software is available to process the images, histograms and curve-type data. |

|

Specifications

|

|

|

Primary applications include: • Open Hole Borehole Imaging. • Fracture Detection. • Casing Inspection (Both Thickness And Diameter). • Ultrasonic Cement Evaluation/ Imaging. |

|

CAST-V HAS BEEN USED POPULARLY BY L&TD, VSP FOR STUDYING THE CHARACTERISTICS OF FRACTURES IN BASEMENT, The energy levels of reflected ultrasonic wave have been used: - To locate the fracture zones. - To differentiate between open fractures and filled fractures. - To determine the geometric characteristics of fractures: dip, azimuth dip, and aperture. In fact, surveys in basement of Cue long basin indicated that CAST-V is the most effective tool for studying basement fractures. |

|

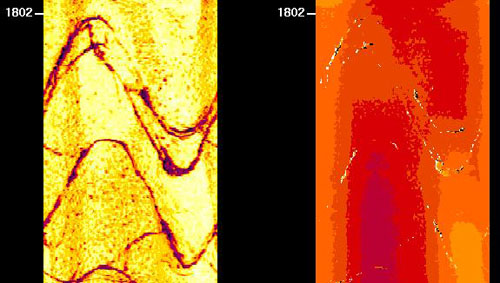

This open-hole CAST-V imaging was logged from fractured basement reservoir of White Tiger oil field. The upper plot shows clearly the open fractures both on amplitude (left) and transit time (right). These fracture zones are highly productive zones. |

|

This plot clearly shows the closed fractures both on the amplitude (left) and transit time (right). These fracture zones are non-productive zones |

|

A productive zone was identified by CAST-V and traditional log (LLD, LLS, DT, NPHI, RHOB etc) measurements. This was confirmed with production logging data |

Nhóm Marketing

Casing Inspection by 40-60 Fingers MIT

|

DESCRIPTION

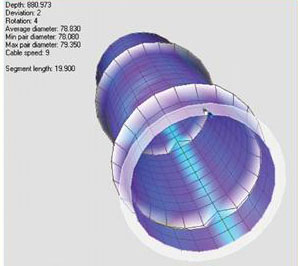

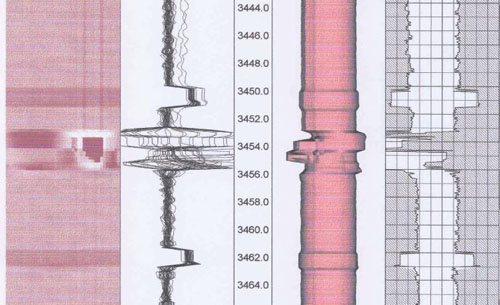

The Sondex 40 and 60 finger MITs have been designed to provide the most accurate casing caliper measurements in the industry. The high quality of the data allows for 3 dimensional imaging and the calculation of rates of corrosion or scale deposition. OPERATING PRINCIPLE The tool is run in the hole using mono-conductor cable or Slickline. Once at the bottom of the logging interval the fingers and integral centralisers are motored open. The spring loaded, hardened tip fingers push against the ID of the casing or tubing with a low constant force. As the tool is logged up the well, the movement of each finger is transferred to a position sensor. The output of the position sensor is then digitised for recording into memory or transmission uphole. Data from each finger is monitored independently. At the end of the run the fingers are motored closed for pulling out of hole or for repeat logging. The tool contains an inclinometer to denote the high side and well deviation. The temperature of the electronics is monitored for software correction of sensor drift.

Application: • Quantification of scale build up and corrosion. • Accurate location of holes or anomalies. • Identification of tubing items and damage.

INTERFACES & TOOL COMBINATIONS Switchable for operation with other PLT tools (Ultralink only).

SPECIFICATIONS

|

|

Up to now, Vietsovpetro L&TD has conducted more than 250 jobs of csing inspection using Sondex MultiFinger Image Tools in Vietsovpetro’s oil fields. The result of these surveys have allowed the company to plan the proper solution for remedial works. This is a very reliable, flexible tool with little less operation cost. It can be used in any well conditions (oil, gas, water, mud). The pictures below are typical cases of broken casings observed in White Tiger production wells using 40-60 fingers MIT tools. |

|

|

|

|

|

|

Nhóm Marketing

Fluid Density

|

DESCRIPTION

The Sondex FDR provides a reliable, durable and comparatively safe means of measuring fluid density at all well deviations. The tool uses a low energy Americium‑241 gamma ray source with radiation levels approaching background at a distance of only one metre from the tool. The tool has been re‑designed to be immune to the effects of radioactive scale. A radiation shield is provided which can be locked on the tool so that the source can be left in place between jobs. As the tool is unaffected by gravity or pressure fluctuations, it is able to operate reliably in all orientations from vertical to horizontal, and at all flow rates.

OPERATING PRINCIPLE Gamma rays are emitted by the RA source at one end of a measuring cell through which the well fluid passes. At the opposite end of the cell a scintillation detector provides a count rate which is a logarithmic function of the fluid density. The scintillation detector is temperature stabilized and matched to the gamma energy of the source. The tool may be calibrated in air and fresh water using Sondex supplied multipliers to derive calibration values applicable to oil and saltwater densities. SPECIFICATIONS

|

|

BENEFITS:

|

|

|

|

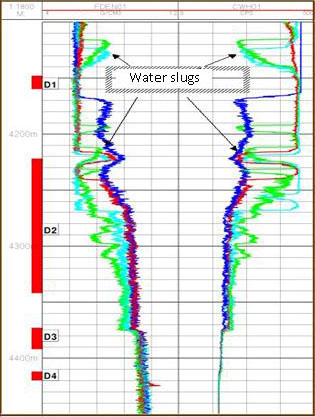

The combination of capacitance & density tool is helpful to identify the patterns of fluid flow in vertical / horizontal / highly deviated wells... |

Nhóm Marketing