L&TD

LOGGING & TESTING DIVISION

Case - Hole Logging

Tubing Inspection by 24 Fingers MIT

|

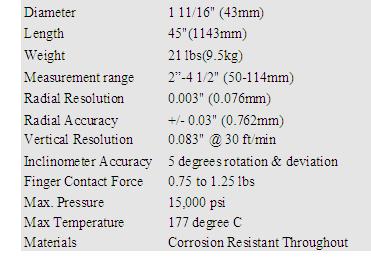

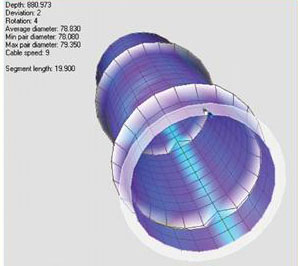

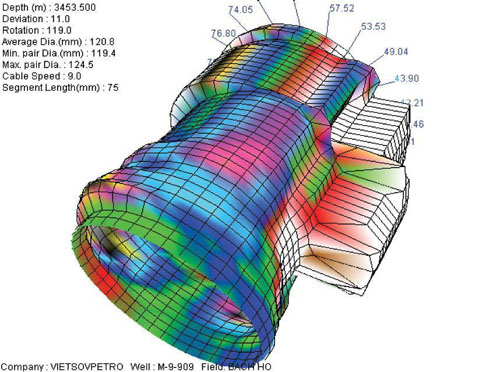

DESCRIPTION The Sondex 24 finger MIT has been designed to provide the most accurate tubing caliper measurements in the industry. The high quality of the data allows for 3 dimensional imaging and the calculation of rates of corrosion or scale deposition. OPERATING PRINCIPLE The tool is run in the hole using mono-conductor cable or Slickline. Once at the bottom the fingers are motored open. The spring loaded, hardened tip fingers push against the ID of the casing or tubing with a low constant force. As the tool is logged up the well, the movement of each finger is transferred to a position sensor. The output of the position sensor is then digitized for recording into memory or transmission up hole. Data from each finger is monitored independently. At the end of the run the fingers are motored closed for pulling out of hole or for repeat logging. The tool contains an inclinometer to denote the high side and well deviation. The temperature of the electronics is monitored for software correction of sensor drift. APPLICATIONS • Quantification of scale build up and corrosion. • Accurate location of holes or anomalies. • Identification of tubing items and damage. INTERFACES & TOOL COMBINATIONS Switch-able for operation with other PLT tools (Ultralink only). OPTIONS Stainless Steel or Beryllium-Copper Fingers. Memory or Surface Readout (Slickline or Mono-conductor cable) MITpro statistical joint analysis software MITview 3D imaging software SPECIFICATIONS (1 11/16" 24 FINGER MIT)

|

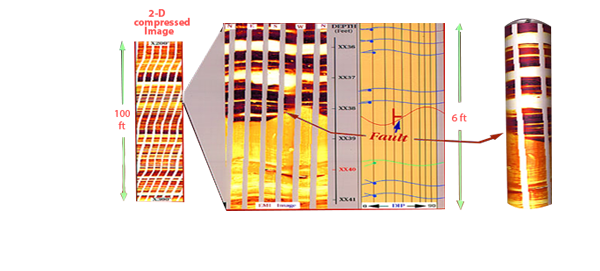

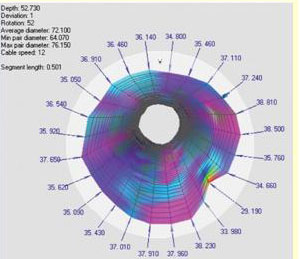

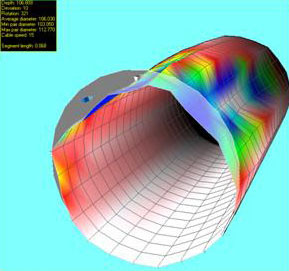

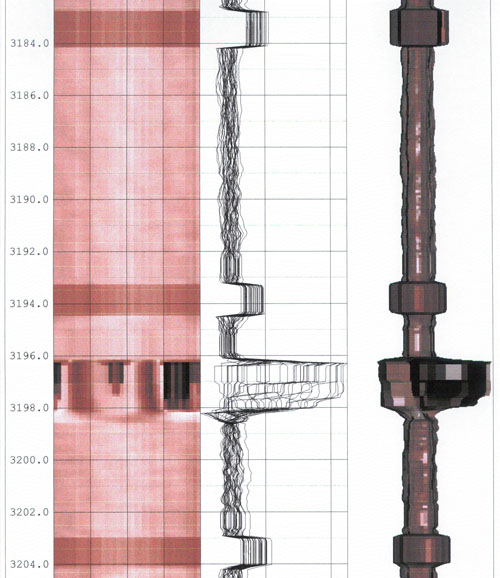

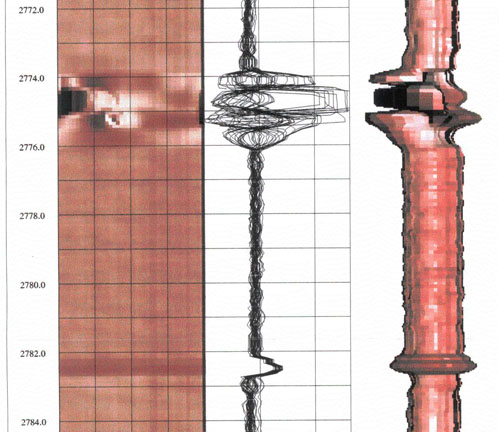

| The MIT-24 is widely used for tubing inspection in Vietsovpetro’s oil fields. Pictures below show some results of 1-11/16“ OD 24 FINGER MIT TOOL. |

|

|

|

|

|

|

Nhóm Marketing

Casing Inspection by 40-60 Fingers MIT

|

DESCRIPTION

The Sondex 40 and 60 finger MITs have been designed to provide the most accurate casing caliper measurements in the industry. The high quality of the data allows for 3 dimensional imaging and the calculation of rates of corrosion or scale deposition. OPERATING PRINCIPLE The tool is run in the hole using mono-conductor cable or Slickline. Once at the bottom of the logging interval the fingers and integral centralisers are motored open. The spring loaded, hardened tip fingers push against the ID of the casing or tubing with a low constant force. As the tool is logged up the well, the movement of each finger is transferred to a position sensor. The output of the position sensor is then digitised for recording into memory or transmission uphole. Data from each finger is monitored independently. At the end of the run the fingers are motored closed for pulling out of hole or for repeat logging. The tool contains an inclinometer to denote the high side and well deviation. The temperature of the electronics is monitored for software correction of sensor drift.

Application: • Quantification of scale build up and corrosion. • Accurate location of holes or anomalies. • Identification of tubing items and damage.

INTERFACES & TOOL COMBINATIONS Switchable for operation with other PLT tools (Ultralink only).

SPECIFICATIONS

|

|

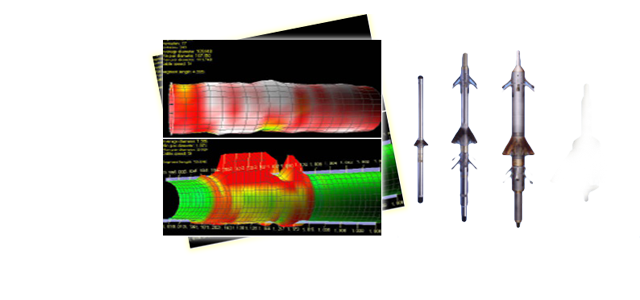

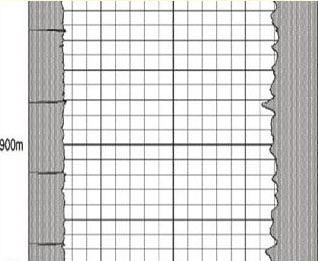

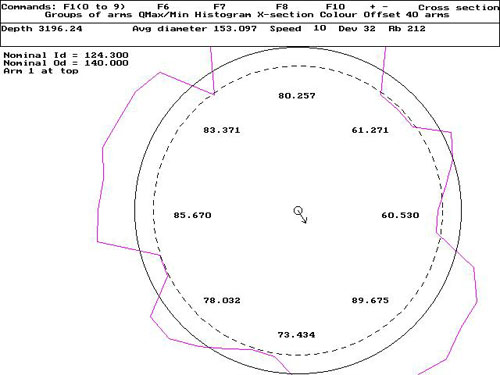

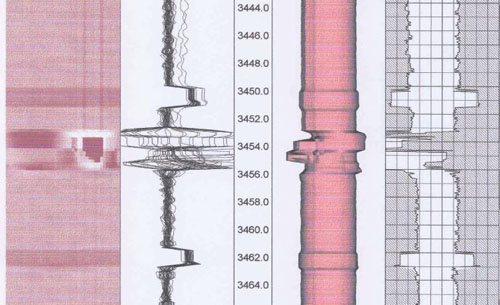

Up to now, Vietsovpetro L&TD has conducted more than 250 jobs of csing inspection using Sondex MultiFinger Image Tools in Vietsovpetro’s oil fields. The result of these surveys have allowed the company to plan the proper solution for remedial works. This is a very reliable, flexible tool with little less operation cost. It can be used in any well conditions (oil, gas, water, mud). The pictures below are typical cases of broken casings observed in White Tiger production wells using 40-60 fingers MIT tools. |

|

|

|

|

|

|

Nhóm Marketing

Casing Inspection CAST-V

| The newest generation Circumferential Acoustic Scanning tool, the CAST-V made by Halliburton, provides a wealth of information in both open and cased holes. In cased holes, ultrasonic pipe inspection and cement evaluation can now be obtained simultaneously. In open holes, the CAST-V provides complete borehole imaging for accurate formation evaluation.

Operating over a wide range of downhole environments, the CAST-V data can be presented in a variety of two- and three- dimensional formats. Powerful, yet user-friendly imaging analysis software is available to process the images, histograms and curve-type data. |

|

Specifications

|

|

|

Primary applications include:

|

| CAST-V – A COST-EFFECTIVE TOOL

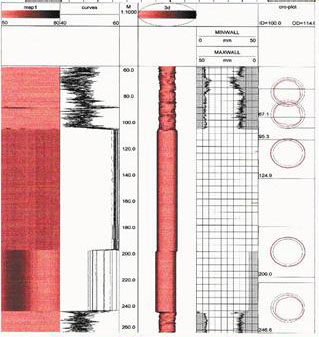

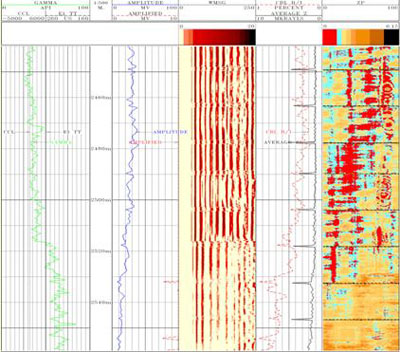

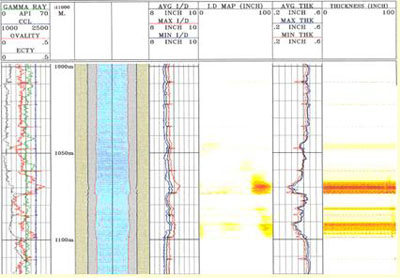

FOR CASING INSPECTION AND CEMENT EVALUATION. CAST-V has been used by Vietsovpetro L&TD for casing inspection and cement evaluation. Cased hole diagnostic applications provide the following information: - Detailed radial caliper information, precise perforation location, - Casing damage inspection, corrosion effects description, real pipe wear identification. - Evaluation of complex and lightweight cement |

|

This plot of casedhole logs displays VDL in Track 3 and Impedance map in Track 5. They clearly indicate that interval 2440-2532 m, cement bonding is poor, the lower shows good bonding. |

|

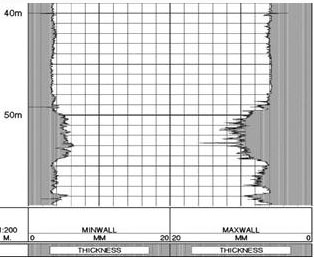

This plot of casedhole logs displays I.D map in Track 4 and Thickness map in Track 6. They clearly indicate corrosions in interval 1060-1100m |

Nhóm Marketing

1. INTRODUCTION

- Formed in 1991

- Consist of

- 02 Production wire-line teams

- 02 Casing inspection teams

- 01 Memory team. ( in 2003)

- Personal : 21

- Engineer: 12

- Skilled worker: 9

- Perfomed

- Over 300 PLT jobs

- Over 200 Casing/tubing inspection jobs