L&TD

LOGGING & TESTING DIVISION

Sản phẩm dịch vụ

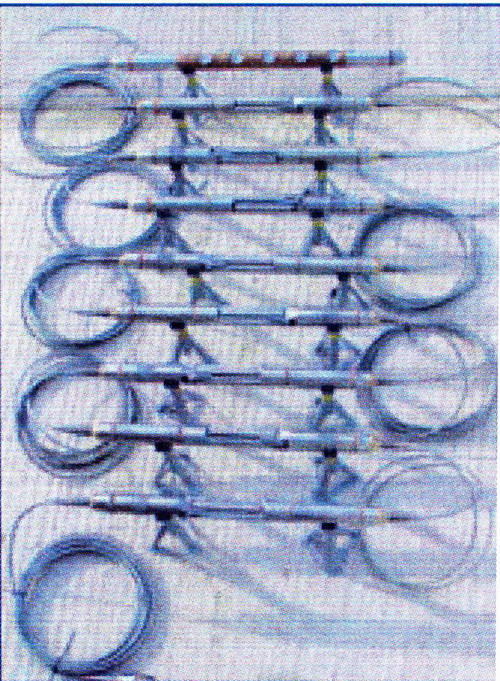

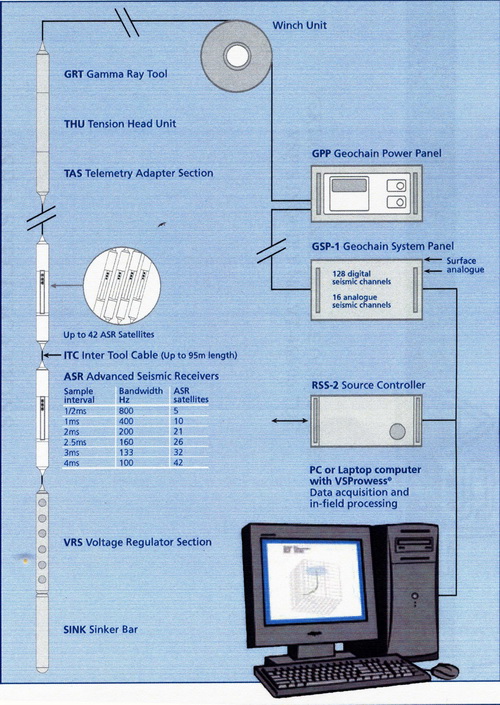

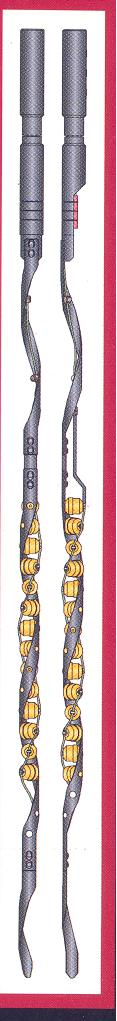

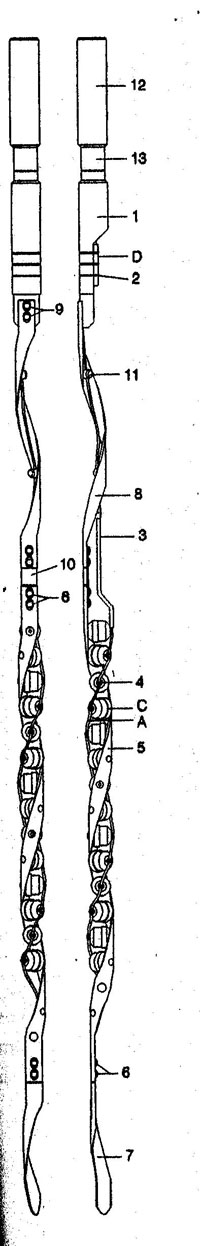

Downhole Tool GeochainTM 42 Level Digital VSP Array

|

Main Features: • Up to 42 satellites • Standard 7 conductor wireline. • Real time data transmission • 3 component gimballed • 24bit Delta-Sigma convertors • 180oC temperature rating • Unique Active Cooling System for continuous operation at 180oC • 20000psi pressure rating • Up to 95m between satellites |

8 satellites and VRS |

|

GeochainTM – an 8 level array with VRS

|

Nhóm Marketing

WaveSonic Log

|

WAVE SONIC - Halliburton's Third Generation Ultra-Reliable, Crossed Dipole Sonic Tool THE BETTER KEY TO FRACTURE RESERVOIR EVALUATION |

|

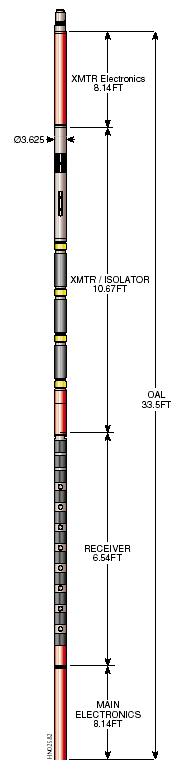

Tool specification

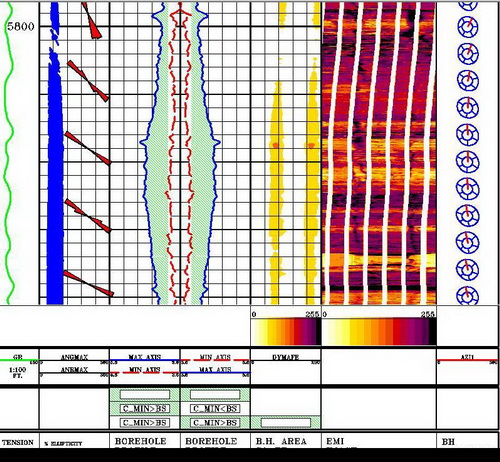

Halliburton's WaveSonic crossed dipole sonic tool makes it easy to determine fast and slow shear wave travel times and their orientation in the formation. With the WaveSonic, you can even calculate minimum and maximum principal stresses and stress field orientation by combining oriented slowness data with overburden and pore pressure data. This information is vital for mechanical analysis, wellbore stability and production enhancement treatment design. Sonic anisotropy and the orientation of the anisotropy can be used to determine the orientation of natural fractures. Sonic attributes such as P wave slowness, fast and slow shear wave travel time, identification of compressive fluids in the pore space, and anisotropy orientation allow for better 3 D seismic analysis. |

|

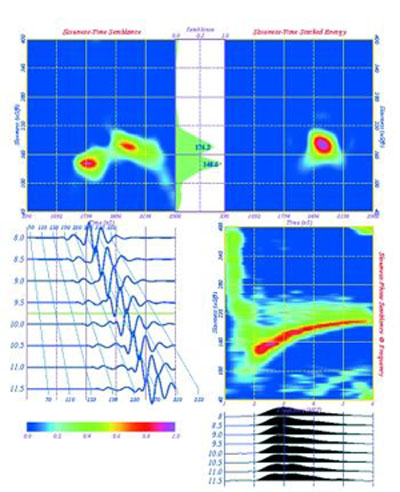

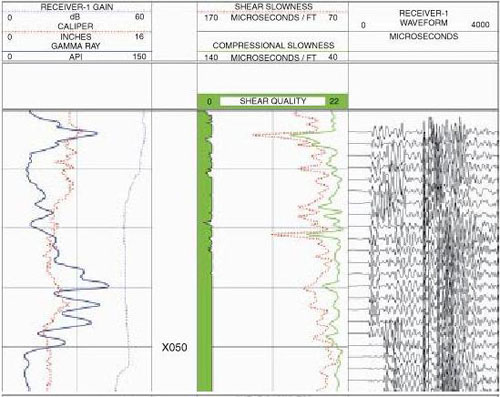

This is an example of a semblance diagnostic plot of the waveform data from the eight waveforms. In the circle is a section of a WaveSonic log showing Monopole P wave slowness and semblance quality monopole refracted Shear wave |

| The Product of Halliburton’s WaveSonic tool service provides simultaneous monopole and crossed dipole sonic information. P‑wave and S‑wave slowness can be obtained in formation conditions ranging from poorly consolidated high porosity gas saturated sandstones to low porosity carbonates. The flexural wave energy is propagated from a low frequency on‑depth crossed dipole bender‑bar source. The low frequency flexural wave travels at the true shear slowness of the formation. As a result, dispersion corrections for shear have slowness are not required. A low frequency monopole source is utilized, so the P‑wave and flexural wave data have similar depths of investigations well beyond any near wellbore alteration. Other benefits include:

- No need for dispersion corrections for slowness determination. ‑ No depth shifting of waveform data for anisotropy analysis.

|

Nhóm Marketing

Flowmeters

|

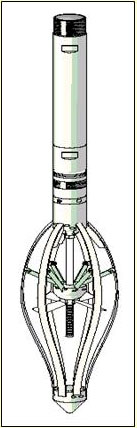

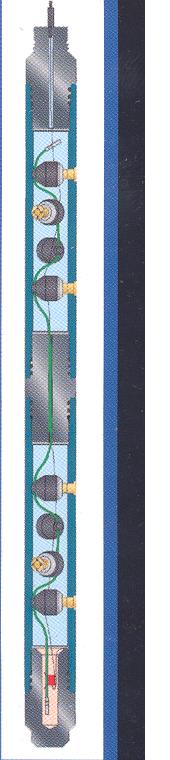

DESCRIPTION The Continuous Spinner Flowmeter are disgned for logging in tubing or sand screened well. The spinner rotates continuously and is supported by roller bearings each end. This performs in all well orientations from vertical to horizontal, in very high fluid velocity such as gas wells. The Caged Full Bore Flowmeter – CFB provides added protection to its impeller when used in wells with large ID gas lift mandrels and in horizontal wells. By allowing a large diameter impeller to pass through small diameter tubing, accurate flowrates covering a large cross section of the casing may be measured.

OPERATING PRINCIPLE CFS: The spinner is mounted between roller bearings and rotation detection is through zero drag Hall effect devices, giving very low threshold and optimizing low flow measurement at high flowrate. CFB: it may be closed down to tool diameter while running or pulling out of hole, and opens automatically to casing size when it leaves the tubing to enter the casing. Should a restriction be encountered during logging, the flowmeter will close and fold the spinner until the restriction is passed, thus avoiding damage to the blades.

SPECIFICATIONS |

||||||||||||||||||||||

|

|

|

|

APPLICATIONS

CFS: Production Profile in Tubing across Sliding Side Doors. Offers better protection in wells with debris.Logging inside sand screens/slotted liners. Injection MonitoringCFB:

Horizontal and Highly Deviated Wells Full Bore Production Profile Full Bore Injection Profile Low Flow Rates The Flowmeters have been used by VIETSOVPETRO L&TD since 1991 with more than 200 jobs conducted in over 100 wells of White Tiger and Dragon Field |

| Downhole multiphase flow likely encountered in production well.

Production logging in multi-phase flow wells has the same target as in the single-phase wells, as isolated interval detection anomalous rate changes clarification.

|

|

Nhóm Marketing

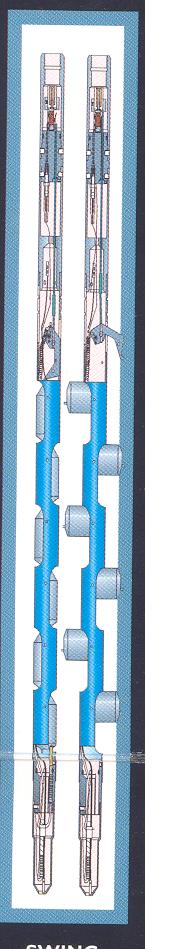

Thru Tubing Perforation System (Swing Jet-180 Phased System)

|

Specifications

Benefits and Features - Swing jet can perforate at under balanced and makes the shell crater deeper (about 10 ”) in formations. - Swing jet makes increasing recovery factor and can pass through Christmas tree, tubing … and perforate under packer. - Swing jet can perforate during production. - Swing jet carries larger charges than reguler through tubing guns. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Specifications

|

||||||||||||||||||||

Benefits and Features Makes increasing recovery factor of hydrocarbon saturated zone in oil fields. - Can pass through Christmas tree, tubing. - Can perforate under balance and under packer. - Can perforate during producing process. - The length of the gun may be up to 10 meters. |

|

|

Nhóm Marketing

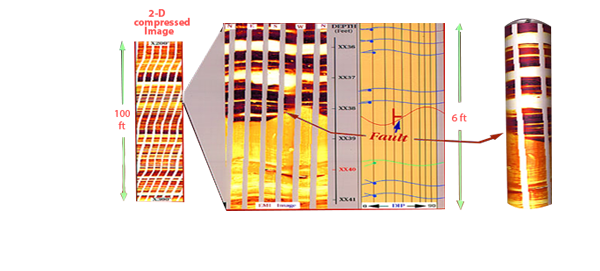

Imager Analysis

|

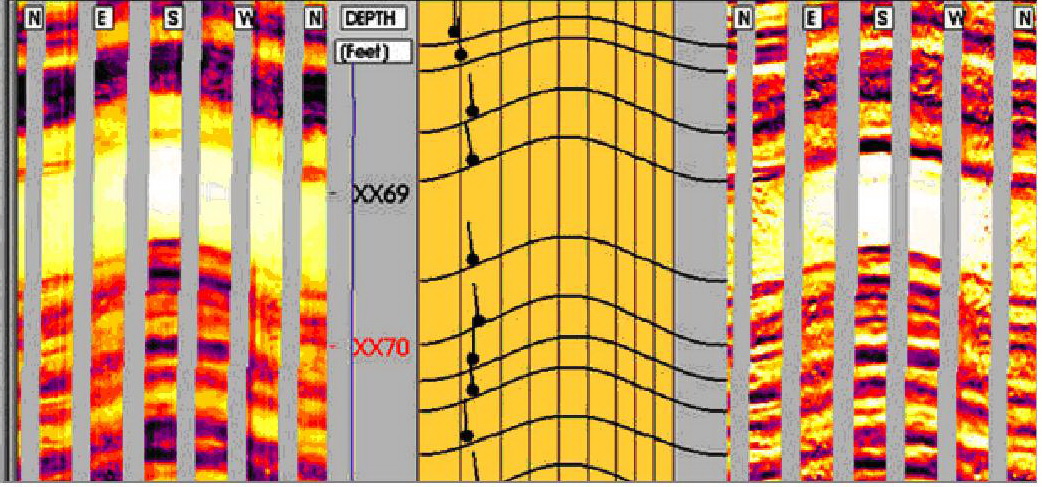

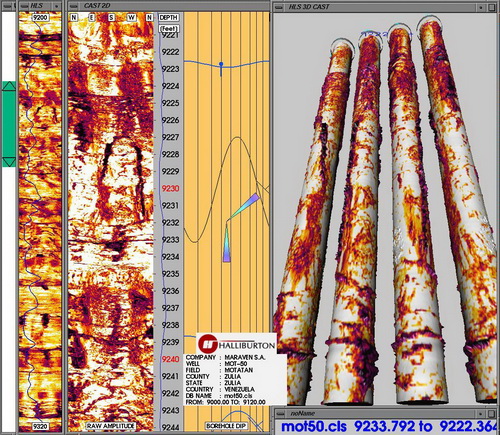

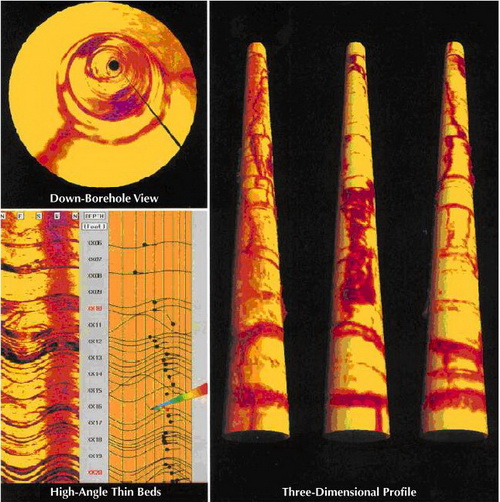

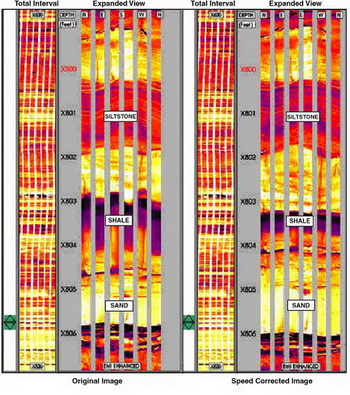

Imager is an interactive image interpretation software package used to present and analyze vector data from the Circumferential Acoustic Scanning Tool (CAST), Electric Micro Imaging (EMI) tool, the Formation MicroScanner™ (FMS) tool, and the Fullbore Formation MicroImager (FMI) tool. Imager allows displaying the logged data graphically in various ways. The images may be enhanced to emphasize certain features, facilitating the interactive calculation of dip and fracture information.

For CAST service, Using Imager, we can:

For EMI Service, using Imager, we can:

Calculate the dip angle and direction of bedding, fractures |

|

Comparison of EMI Images with speed correction applied. |

|

Imager analysis program window Geometry and Stress analysis |

Nhóm Marketing

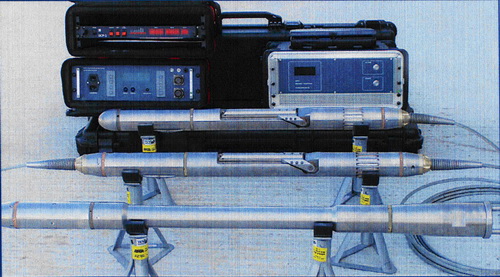

Downhole Tool ASR-1 Advanced Seismic Receiver

The ARS-1 Specifications

General

The ASR geophones a compact three component electromechanical downhole geophone. It is disigned for use in wells up to 20000psi and 200oC and provides fast arm cycle time with an arm force to weight ratio of 5:1.

Locking Arms The standard arm will accommodate boreholes from 5” to 13”, the short arm will accommodate borehole from 3 ½” to 9” and an extended arm can be use to increase this range to 22”. The locking force is constant to within 20% throughout its operating range and will lock into 9 5/8” casing in fifteen seconds when fitted with the standard arm. Gimbal Element The tool is provided with a three component gimballed package as standard using one high sensitivity SM4 high temperature element per axis. The gimbal assembly with faithfully follow any borehole deviation from vertical through to horizontal and slightly beyond. Nhóm Marketing |

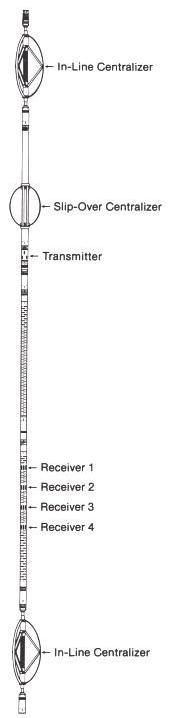

FullWave Sonic Log

|

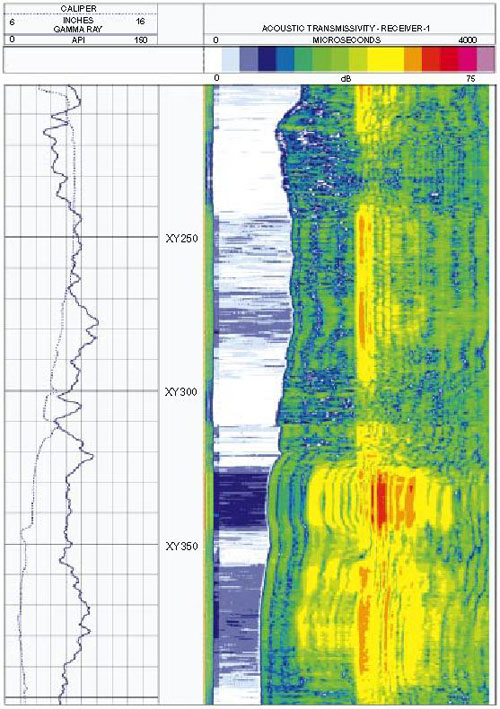

The sonic logging system developed by Halliburton provides more acoustic information than ever before. From 1997, Vietsopetro L&TD successfully evaluated potential zones in fractured basement using FWST data.

Using a piezoelectric transmitter and four long‑spaced receivers, the FWS system records the entire acoustic wavetrain. Digital processing techniques extract compressional, shear, and Stoneley t; shear wave and compressional wave amplitudes; and Stoneley wave attenuation. These basic measurements provide valuable information on rock types, gas zones, porosity naturally fractured intervals, formation elastic properties, stress field around the borehole, permeability, and acoustic impedance.

FWS APPLICATIONS

|

|

FWST – An effective tool to evaluate the potential zones in fractured basement.

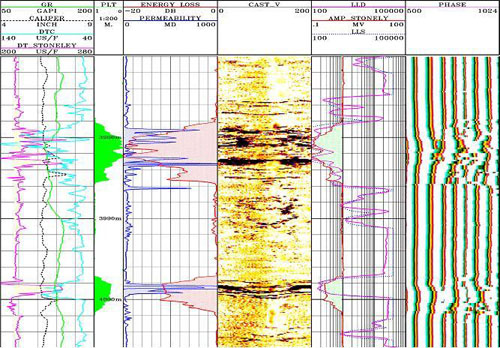

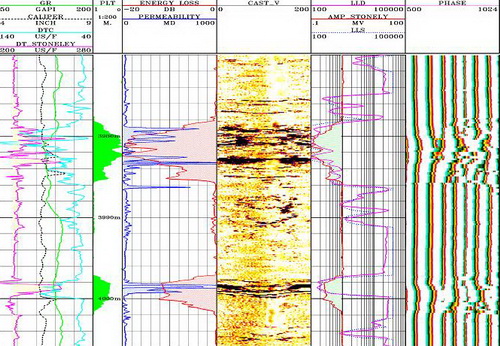

FWST has been used by Vietsopetro L&TD to investigate the characteristics of fractures in basement of Cuu Long basin. The tc, ts and tst and energy attenuation measurements have been used for: - Detection of naturally fractured zones. - Indication of permeability variations with depth from Stoneley wave attenuation. - Lithology identification by means of velocity ratio, ts /tc In fact, surveys in basement of Cuu Long basin indicated that FWST is an effective tool for evaluation of fracture zones in basement. |

|

This FWS primary log example displays the raw waveform data from Receiver 1 in the right track. Processed results, including compressional and shear slowness curves (tc and ts), are shown in the center track, along with a shear slowness quality indicator Caliper and Gamma Ray information, along with a gain curve, are displayed in the left track |

|

Instantaneous Waveform Characteristics IWC analysis allow users better evaluation of fracture zones as spectrum of amplitude, phase and frequency of waveform |

|

This plot shows potential zones in White Tiger fractured basement by mean of the energy loss of Stoneley wave (Track 5). In fact, these zones are highly productive. |

Nhóm Marketing

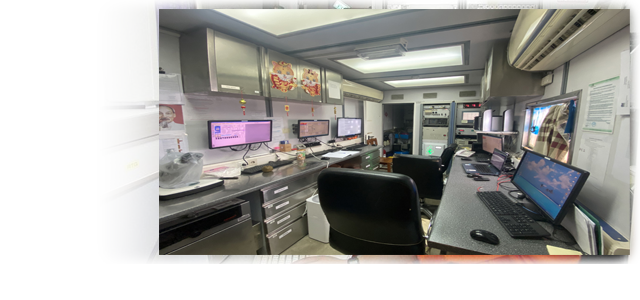

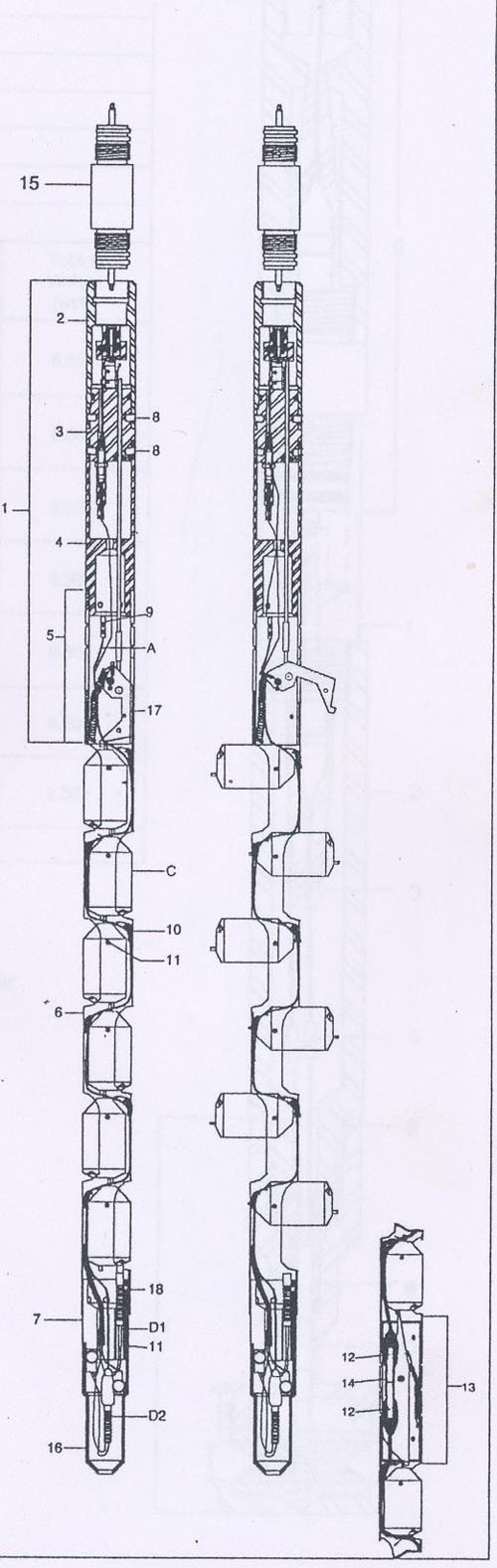

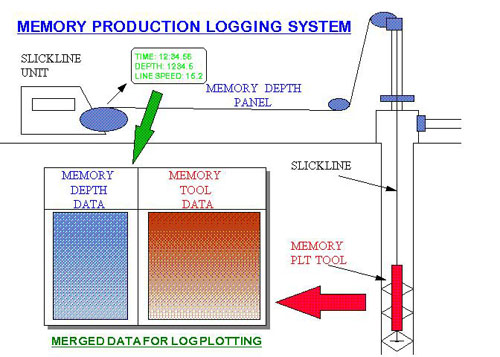

Memory Production Logging System

|

In memory production logging the production logging tools are run on non conducting wireline (slickline) or on coiled tubing. Power is supplied by a lithium battery at the top of the string. Instead of data being sent up the line the telemetry is decoded and data is stored in a memory tool according to a pre-programmed sample rate. Simultaneously depth and line speed data is recorded at surface in memory. After the tools are recovered from the well the two sets of data are merged with output files in ASCII format of depth, line speed and tool responses. These ASCII files are read into log plotting software and after depth correlating plotted as production logs.

|

|

Nhóm Marketing

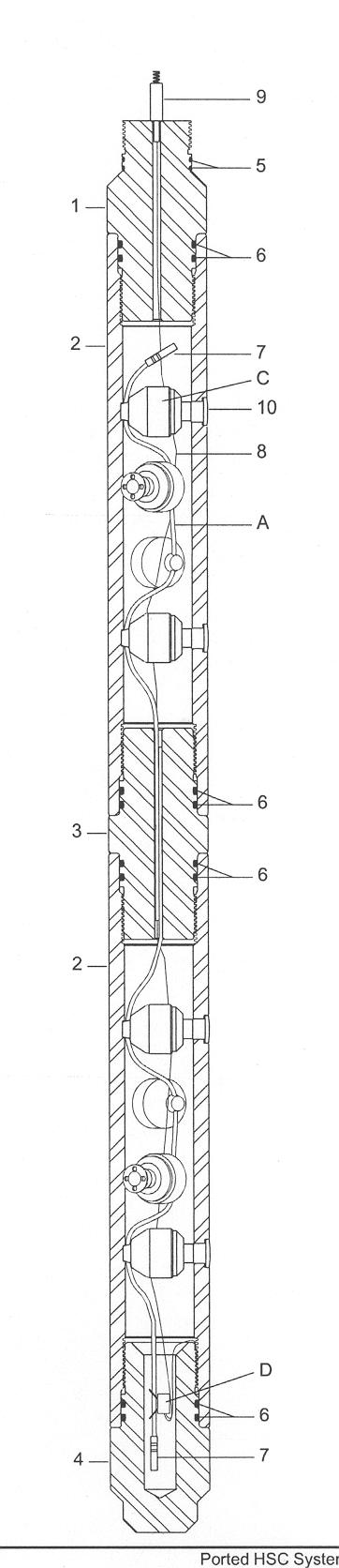

Wireline Perforation 3-3/8, 4-1/2,5 & 7" Deep Penetrator

|

||||||||||||||||||||||||||||||||||||||||||||||||||

L & TD has used this equipment since 1988 in hundreds wells. These wells were located at Bach Ho, Dai Hung and Rong oil fields. The angle of wells may have been to 70 degrees and the depth up to 5000 m.

This equipment can be uesd without cutting off electric supply.

Wireline perforation has been used very safely in our oil field’s. Advantages of wireline perforation is the gun can not fire if hydrostatic pressure less 10 atm and the length of the gun may be from 3 to 8 meters. |

|

|

|

|

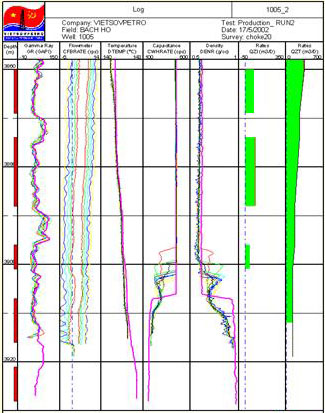

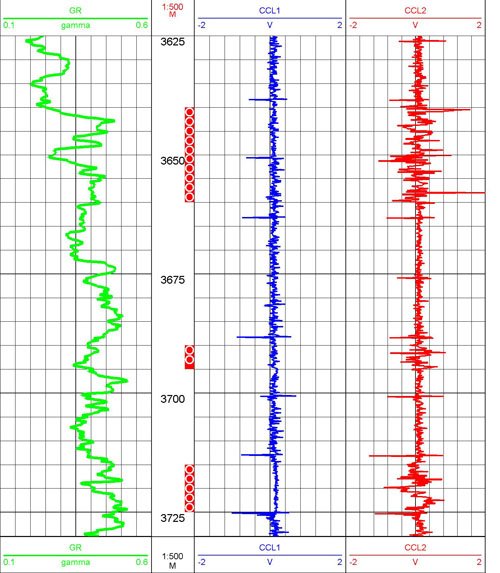

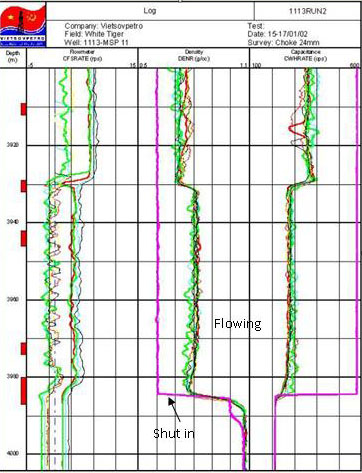

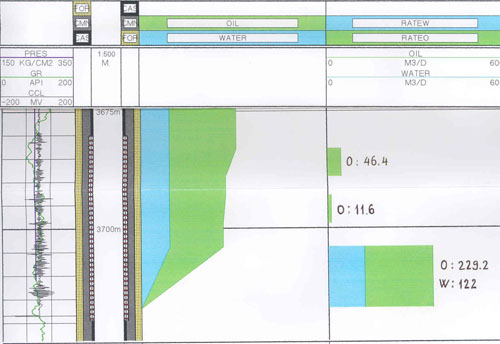

The picture shows, the well after perforation using a wireline gun. - Density: 20 charges per meter. - Gun size: 3-3/8”. - Perforation intervals: 3640-3660, 3690- 3695 and 3715-3725m |

|

This picture shows the result of production logs after perforation using a wireline gun for a production well in basement - Shot density: 20 charges per meter. - Gun size: 3-3/8”. - Perforation intervals: 3680 - 3719.5 m. |

Nhóm Marketing

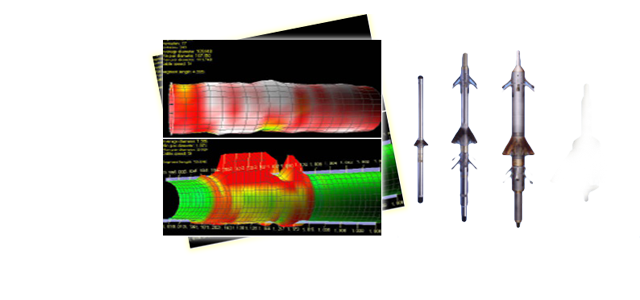

Full Wave Sonic Analysic

|

FULL WAVE SONIC tool measures compressional wave, shear wave and stoneley wave in a waveform.

*FullWave module. Using a fullwave module we can present and analyze fullwave acoustic data. The program allows displaying the logged data graphically in many ways. The data images can be enhanced to emphasize certain features. The following analysis techniques are available with FullWave:

Beside that, FullWave module allows the use of Kaiser and Finite Impulse frequency filters and from that we can see and analyze compressional wave, shear wave or stoneley wave independently. *RockXpertTM Analysis module. Critical Information for Fracture Designs and Well Plans

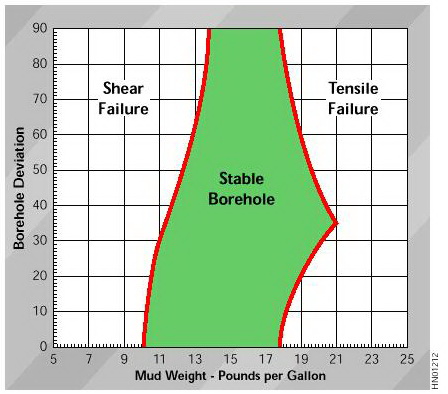

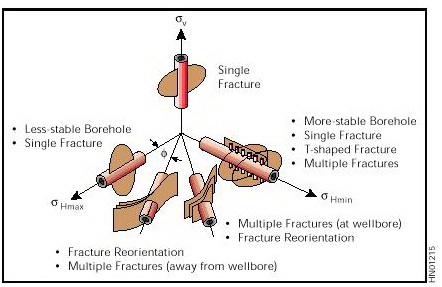

|

|

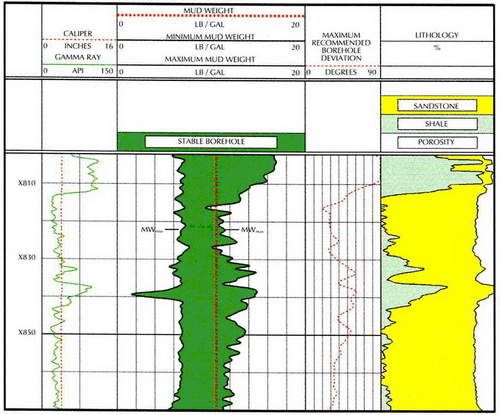

The declination of a horizontal wellbore with respect to the principal horizontal stress can have a significant effect on wellbore stability and fracture geometry. RockXpert logs can aid in well planning to minimize borehole instability and to maximize the effectiveness of fracturing operations. |

|

At any specified point along a proposed or existing well path, RockXpert analysis can identify stable borehole conditions as a function of mud weight and borehole deviation. |

RockXpert logs indicate the safe mud-weight range to provide sanding and formation breakdown, as shown in Track 2. The logs also include gamma and caliper curves in Track 1, predicted maximum borehole deviation in Track 3, and lithology information in Track 4. |

|

STRES, FRACHT, FRACPAR, FWSIWC modules allow us to estimate:

|

|

This plot shows potential zones in White Tiger fractured basement by means of the energy loss of Stoneley wave (Track 5), in fact, these zones are highly productive |

Nhóm Marketing

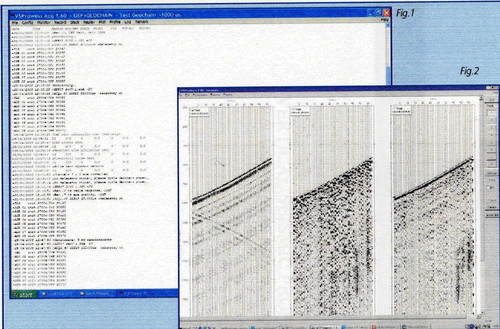

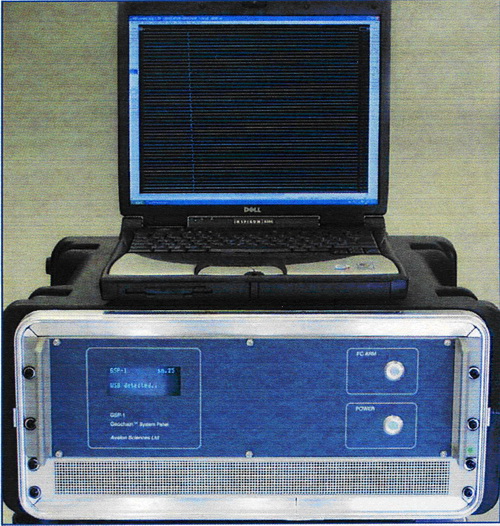

Surface Equipment GSP-1 VSP Data Acquistion System

|

• Up to 16 analogue channels • 512 Kb digital interface • 24bit Delta-Sigma convertors • Built in firing circuit • Full instrument tests • USP interface • Use standard PC running VSProwess software Specifications Analogue section |

|

Digital section

General

|

|

Functionality

Communication with the PC recording system is by

The GSP incorporates a single airgun firing circuit for use on simple checkshot surveys. For independent external control circuits give control over external source controllers such as our own RSS four gun remote gun firing system

|

The GSP-1 in use with a Dual analogue system |

| The panel provides fully automatic DC offset and gain calibration along with full instrument tests. The I-test reports are generated on the PC for archiving or for passing on to the client.

Fig1: Acquisition Observer Log Fig2: Stack plot of vertical and horizontal components. |

Nhóm Marketing