L&TD

LOGGING & TESTING DIVISION

Flowmeters

|

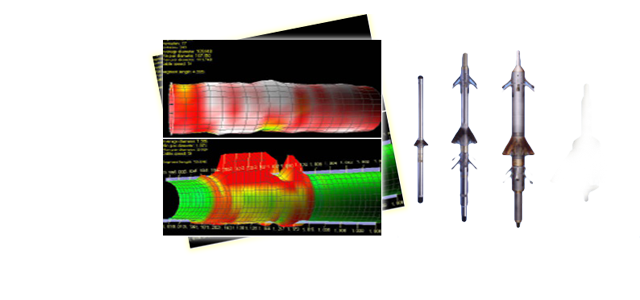

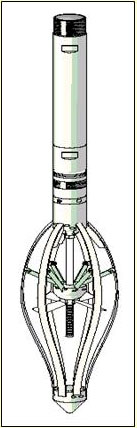

DESCRIPTION The Continuous Spinner Flowmeter are disgned for logging in tubing or sand screened well. The spinner rotates continuously and is supported by roller bearings each end. This performs in all well orientations from vertical to horizontal, in very high fluid velocity such as gas wells. The Caged Full Bore Flowmeter – CFB provides added protection to its impeller when used in wells with large ID gas lift mandrels and in horizontal wells. By allowing a large diameter impeller to pass through small diameter tubing, accurate flowrates covering a large cross section of the casing may be measured.

OPERATING PRINCIPLE CFS: The spinner is mounted between roller bearings and rotation detection is through zero drag Hall effect devices, giving very low threshold and optimizing low flow measurement at high flowrate. CFB: it may be closed down to tool diameter while running or pulling out of hole, and opens automatically to casing size when it leaves the tubing to enter the casing. Should a restriction be encountered during logging, the flowmeter will close and fold the spinner until the restriction is passed, thus avoiding damage to the blades.

SPECIFICATIONS |

||||||||||||||||||||||

|

|

|

|

APPLICATIONS

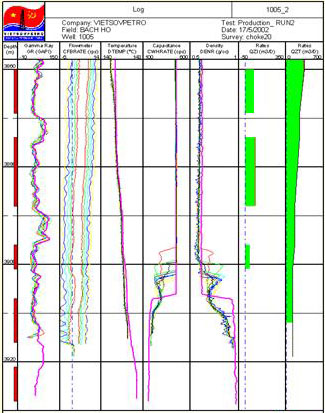

CFS: Production Profile in Tubing across Sliding Side Doors. Offers better protection in wells with debris.Logging inside sand screens/slotted liners. Injection MonitoringCFB:

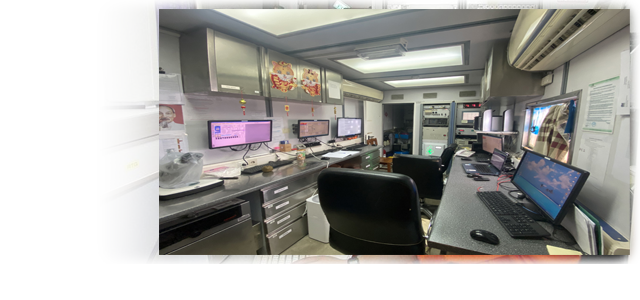

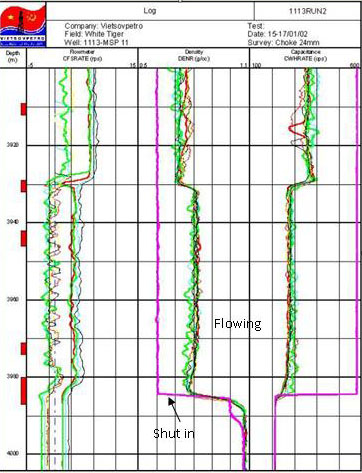

Horizontal and Highly Deviated Wells Full Bore Production Profile Full Bore Injection Profile Low Flow Rates The Flowmeters have been used by VIETSOVPETRO L&TD since 1991 with more than 200 jobs conducted in over 100 wells of White Tiger and Dragon Field |

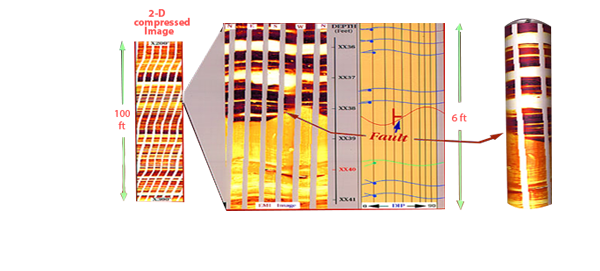

| Downhole multiphase flow likely encountered in production well.

Production logging in multi-phase flow wells has the same target as in the single-phase wells, as isolated interval detection anomalous rate changes clarification.

|

|