L&TD

LOGGING & TESTING DIVISION

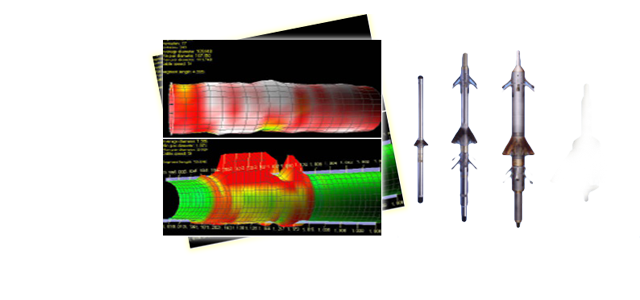

Slip Joints

|

IV. DOWNHOLE TESTING EQUIPMENT Slip Joints A slip joint compensates for the movement associated with ocean heave or temperature change without allowing the movement to disturb the placement of downhole tools. A slip joint operates by balancing its volume. As the slip joint stretches and increases its internal volume, a differential piston within the slip joint allows the same volume of fluid into the pipe. The net result is no change in internal volume. Each slip joint has 5 ft of travel but can be combined with other slip joints to provide additional travel. Slip joints are designed to transmit the torque or rotation required to operate tools such as packers or safety joints. When multiple slip joints are run, they are normally connected together rather than located throughout the pipe string. The number of slip joints required depends on ocean heave and the amount of expected contraction and expansion. Features and Benefits

• Provides a variable-length joint to allow expansion and contraction of pipe during testing or stimulation • Helps space out the workstring when the subsea tree is landed • Keeps vertical movement of drilling vessel from disturbing tool placement • Provides free travel in workstring to reciprocate tools Operation

The weight of the workstring (excluding tools, anchor, and traveling blocks) is used to determine the location of the slip joint. The slip joint(s) are placed above the necessary packer setting weight.When multiple slip joints are used, the top joint makes its complete travel, then the next joint down makes its travel, and so on. The weight indicator may show a slight bump as each slip joint reaches the end of its travel. |

|

Nhóm Marketing