L&TD

LOGGING & TESTING DIVISION

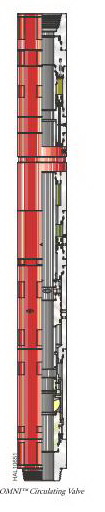

OMNI™ Circulating Valve

|

OMNI™ Circulating Valve The OMNI™ circulating valve is an annulus pressure-operated, recloseable circulating valve. Throughout the operation, the tool is repeatedly cycled up to a predetermined annulus pressure and then released.

The OMNI valve consists of a nitrogen section, an oil system, a circulating valve, and a ball valve. The nitrogen section contains the nitrogen gas that counterbalances the hydrostatic and annulus pressures. The amount of nitrogen in the tool depends on well hydrostatic (mud weight and depth) and downhole temperature. This information must be known to properly prepare the tool for running in. Note: With certain completion fluids, the mud weight at the surface can be significantly different from the actual mud weight downhole.

The operating and control mechanisms are contained in a closed oil system activated by annulus pressure acting on the nitrogen chamber, allowing an unlimited number of pressure cycles.The circulating valve and the ball valve work together to keep circulating pressure off the formation. The ball valve will close before the circulating valve opens. The ball valve closes off the workstring.

Features and Benefits

• Permits well testing, pressure testing, and fluid circulation • Allows unlimited number of pressure cycles

|

| Operation

The well can be flow tested when the valve is in the well test position. When in this position, the circulating ports are closed and the ball valve is opened. During a downhole closure drillstem test, the OMNI valve is in the well test position during flow and shut-in periods. The workstring can be pressure-tested in the blank position because the ball valve closes before the circulating valve opens. Fluid can be pumped in either direction through the tool in the circulating position. In this position, the circulating ports are open and the ball valve is closed.Note: Before the tool is run, the hydrostatic pressure at the specified tool depth must be known. This information is required to obtain the proper nitrogen charging pressure. OMNITM Circulating Valve

Meets NACE-0175 175°F (79°C) standards for H2S service *Service temperature up to 450°F (dressed with 600 series o-rings and PEEK™ back-up seals) **The values of tensile, burst, and collapse strength are calculated with new tool conditions, Lame’s formula for burst and collapse strength, and stress area calculations for tensile strength. ***Pressure rating is defined as differential pressure at the tool. (Differential pressure is the difference in pressure between the casing annulus tool ID.) These ratings are guidelines only. For more information, contact your local Halliburton representative. PEEK is a trademark of ICI Americas, Inc. Poly-Ether-Ether-Ketone. |

Nhóm Marketing