L&TD

LOGGING & TESTING DIVISION

Sản phẩm dịch vụ

Subsurface Testing Equipment

|

III. SUBSURFACE TESTING EQUIPMENT

Ocean Floor Package

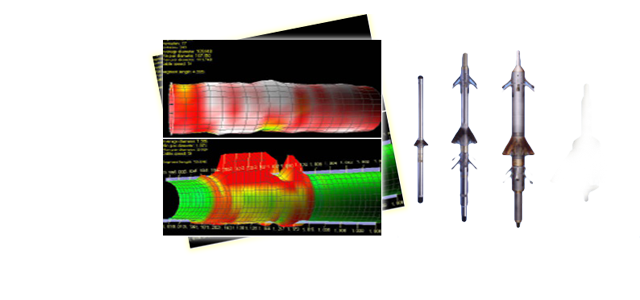

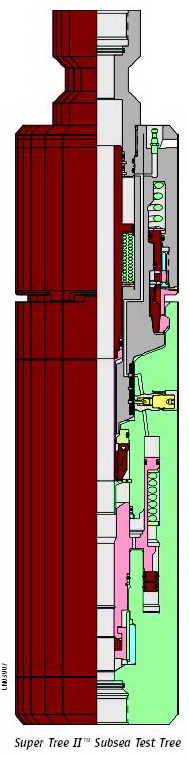

The SSTT consists of two full-pening/normally closed, fail-safe safety valves and a latchrelease connection. The valve section contains two tubing closures. Each closure operates independently of one another, and each relies on a single hydraulic source to hold it open. A normally closed . apper valve and a ball valve are closed by a nitrogen chargeassisted spring force. The nitrogen charge forces the ball to sever wireline or 1.25-in. OD, .125-in. wall thickness coiled tubing. A short time delay between the nitrogen charge and ball/. Apper closure allows severed wireline or coiled tubing to be pulled clear of the . apper before closure. The latch section consists of a latch to the valve section, a flapper-operating piston, and molded seals. The latch section is designed to quickly release the handling string from the SSTT in case of an emergency.

Features and Benefits • Normally closed, fail-safe valve • Releases quickly from the handling string in case of emergency • Functions as a safety device • Maintains pump-through capabilities at all times • Nitrogen dome charge chamber provides increased closing force and lessens the time required for closing • Can unlatch under tension • Redundant seal design • Chemical injection at the valve body, further downhole to an injection sub, or to actuate a sub-surface safety valve • Capable of cutting 2-in. OD, .125 wall-thickness coiled tubing |

|

|

|

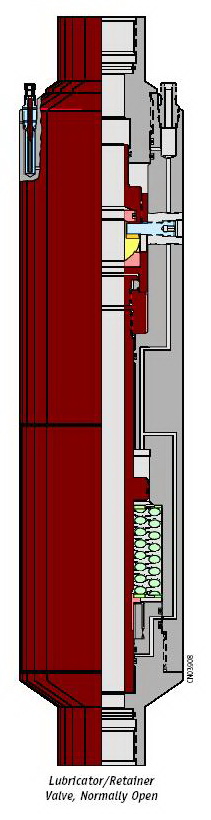

Lubricator/Retainer Valve The Lubricator/Retainer Valve is a tubing-retrievable valve. The placement of the valve in the subsea welltesting string determines whether the tool functions as a Lubricator or Retainer Valve. The valve can function as either a normally open or normally closed/fail-safe ball valve. It is operated from the surface by control lines. When used as a Lubricator Valve, it is installed at a predetermined depth beneath the drill floor. The valve and the workstring above it serve as a lubricator for wireline tools. This installation replaces the need for surfacemounted lubricators. In the lubricator position, the valve can also be used to prove the integrity of the lubricator section by pressure testing from above. When used as Retainer Valve, it is installed directly above the Subsea Test Tree (SSTT) near the ocean floor. Its primary function is to capture well. Fluids that would be trapped in the handling string during an unlatch of the SSTT. Additionally, the valve can be used to prove the integrity of the handling string before the well is brought on line.

Features and Benefits • Retainer dual mode cabilities: normally open or normally closed/fail-safe • Can be used as a Lubricator Valve for wireline tools • Can be used as a Retainer Valve to capture well . uids from the handling string • Normally open holds pressure from below and selectively seals from above |

|

|

Lubricator/Retainer Valve |

| P/N | 617.20100 |

617.20300 |

| OD In (cm) | 10.75 (21.31) | 10.75 (21.31) |

| ID in. (cm) | 3.00 (7.62) | 2.7 5 (6.99) |

| End Connections | 4 1/2 - 4 ACME | 5-4 ACME |

|

Length in. (cm) |

71. 44 (181.46) |

74. 64(198.59) |

| Tensile Rating* lb (kg) |

400,000 (181, 000)) |

400,000 (181,000) |

| Working Pressure** psi (kPa) | 10,000 (69,000) | 15,0 00 (103,500) |

| Service | H2SH | H2S |

| 0 to 350 (-18 to 177) | 0 to 350 (-18 to 177) |

Nhóm Marketing

Surface Testing Equipment

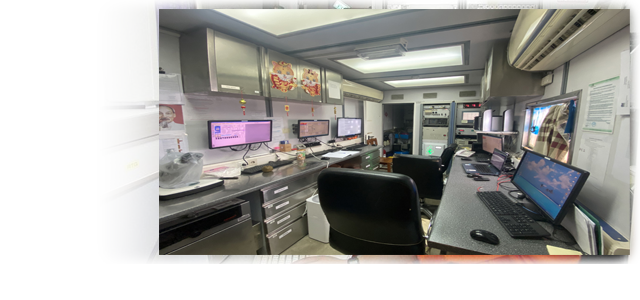

VIETSOVPETRO well testing service was formed since 1987 and has been successfully tested hundreds of wells on White Tiger, Big Bear field , Soi and Hoang Long objects on Vietnam offshore, etc. VIETSOVPETRO well testing team has five highly experienced Engineers, two skilled technicians. Most of them have more than 10 years working experience. Beside of testing on Jack up, Semi Sub sea, Engineers of team also performed testing data analysis, Reservoir parameters are interpreted by Saphir software of KAPPA .co. |

Well Testing

Equipment

- 2 surface fully work-out testing systems supplied by Flopetrol Jonston Co. (Include: Well head, flexible hose, choke manifold, three phases separator, surge tank, transfer pump, pipe work, compressor, burner boom, hydrometer, etc.)

- 1 SubSea equipment supplied by PowerWell Co.

- 2 DownHole equipment (DST) supplied by Halliburton co. ( 2006 year)